|

|

||||

|

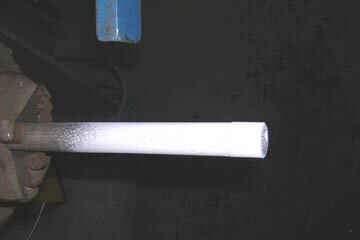

"OWL" ICE-SCREW In the last few years, the evolution of protection on ice has reached levels of absolute excellence both in terms of reliability during the climb and in terms of construction. Ice screws on the market are climbing “instruments” in every sense of the word and to be succinct we can say that the production of bd screws and grivels are essential to people who choose protection in order to reduce the acceptable levels of risk involved in climbing. What comes to mind is whether at this point we really need a new generation of screws and how this seemingly perfect current hand-screw-ice system should be improved. What we can do is propose our solution; a solution that stems once again from Bubu’s experience of moving on precarious surfaces and my obsession for steels. The result is a protection with good manoeuvrability that tries to eliminate the problem of the first stages of insertion. Thanks to the “owl-et” system it’s possible to insert the screw without having to let go and start tightening it again: a sort of jack but a lot lighter. A protection that can be placed anywhere; all you need do is rotate it 60° (1/6 of a turn) in order to tighten it completely. It involves new system of inserting the ice carrot; during its transit inside the piton it finds a diameter which is a few tenths of a millimetre bigger than that of the milling cutter, thereby eliminating internal friction. Above all it’s a mix of 5 stainless steels which makes this screw immune to common corrosive attacks and that makes the structure of this piton reliable up to the highly unlikely climbable temperature of –200°C. Stefano  Temporary version of ice-screw.  Temporary version of ice-screw.  1. separate pieces.  2. pointed pieces.  3. first stage.  4. second stage.  5. post-heating oven.  6. penetrating liquid check.  7. application of penetrating liquids.  8. polishing.  9. welding.  |

back |

||||